Decoding the Cost of Quality: A Comprehensive Guide to Rice Mill Prices

Rice Mill Price: The global demand for rice, a staple for billions, continues to surge, making the rice milling industry a critical component of food security and economic prosperity. For aspiring entrepreneurs and existing millers alike, understanding the intricacies of rice mill prices is paramount. It’s not merely about a single figure; rather, it’s a dynamic interplay of various factors that collectively determine the investment required for a successful and efficient milling operation.

At RiceTec Machinery, we believe in empowering our clients with complete transparency and knowledge. This in-depth guide aims to demystify rice mill pricing, exploring the elements that influence costs, the different scales of operations, and what you can expect when investing in high-quality, reliable machinery.

The Foundation: What Defines a Rice Mill?

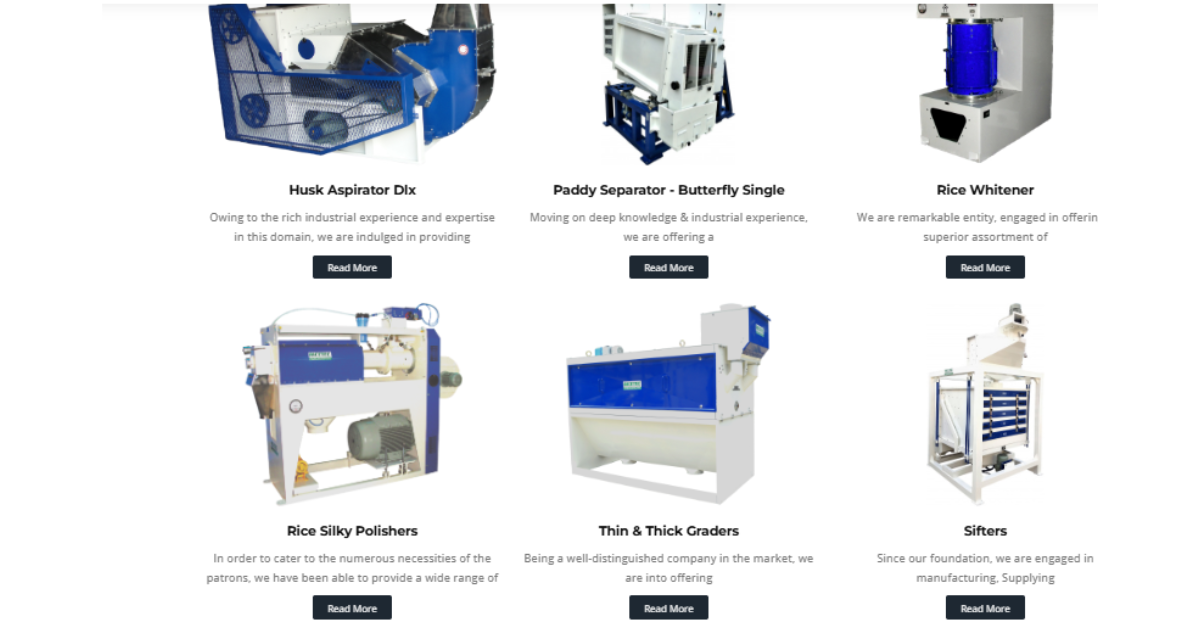

Before delving into prices, it’s crucial to understand what constitutes a modern rice mill. It’s a sophisticated system designed to transform raw paddy into polished, edible rice while minimizing losses and maximizing quality. The process typically involves several key stages, each requiring specialized machinery:

Pre-cleaning

This initial step removes impurities like dust, stones, straw, and immature grains from the raw paddy. Efficient pre-cleaning is vital to protect subsequent machinery from damage and ensure a clean final product.

De-husking (Shelling)

Here, the outer husk is removed from the paddy to produce brown rice. This process often utilizes rubber roll shellers, which are designed for high efficiency and minimal grain breakage.

Paddy Separation

After de-husking, a mixture of brown rice, un-hulled paddy, and husk is obtained. Paddy separators efficiently separate the un-hulled paddy for re-processing, ensuring optimal yield.

Whitening (Polishing)

This stage removes the bran layer from the brown rice, resulting in white rice. Rice whiteners and polishers gently abrade the surface, enhancing the appearance and extending shelf life.

Grading and Sifting

Once polished, the rice is sorted based on size, shape, and quality. Sifters, thin and thick graders, and length graders ensure uniformity and meet specific market demands.

By-product Management

Husk, bran, and rice broken are valuable by-products. Efficient collection and processing systems are crucial for maximizing overall profitability.

Packaging

The final stage involves packaging the milled rice into various sizes and types, ready for distribution.

The “rice mill price” encompasses the cost of acquiring and integrating these machines into a cohesive, operational plant.

Understanding the Spectrum of Rice Mill Prices: From Mini to Mega

The cost of a rice mill varies dramatically based on its capacity and level of automation. Generally, rice mills are categorized into three main scales:

Small-Scale Rice Mills

These are typically suitable for individual farmers, small cooperatives, or those entering the milling business with limited capital.

- Capacity: Often range from 1 ton to 3 tons per hour.

- Machinery: Usually include basic pre-cleaners, a single de-husker, a small whitener, and a simple grading system.

- Automation: Tends to be semi-automatic or manual, requiring more human intervention.

- Estimated Price Range in India: ₹10 lakhs to ₹25 lakhs. (Please note: These are indicative ranges and can fluctuate based on specific models, features, and market conditions.)

- Ideal For: Local consumption, small-scale commercial operations, or as a starting point for expansion.

Medium-Scale Rice Mills

These mills cater to a larger market and offer higher processing capabilities.

- Capacity: Typically range from 4 tons to 8 tons per hour.

- Machinery: Feature more robust and automated versions of the core machines, potentially including multiple whiteners and more sophisticated grading.

- Automation: Often semi-automatic with increased automation in key processes, reducing labor requirements.

- Estimated Price Range in India: ₹40 lakhs to ₹80 lakhs.

- Ideal For: Regional distribution, supplying to medium-sized wholesalers, and meeting consistent demand.

Large-Scale and Fully Automatic Rice Mills

These are comprehensive plants designed for high-volume production and maximum efficiency.

- Capacity: Can process 10 tons per hour, 50 tons per hour, or even 100 tons per hour and above.

- Machinery: Incorporate advanced, fully automated systems for each stage, often including color sorters, sophisticated dust collection systems, and integrated control panels. They prioritize precision, minimal human error, and continuous operation.

- Automation: Fully automatic with PLC (Programmable Logic Controller) systems controlling the entire process, requiring minimal oversight.

- Estimated Price Range in India:

- 10 tons/hour: ₹1.5 crore to ₹2.5 crore

- 50 tons/hour: ₹5 crore to ₹10 crore

- 100 tons/hour and above: ₹12 crore to ₹20 crore+

- Ideal For: Large-scale commercial operations, export-oriented businesses, and those seeking the highest levels of efficiency and product quality.

Key Factors Influencing Rice Mill Price

Beyond capacity and automation, several critical factors contribute to the overall rice mill price:

1. Technology and Automation Level

As highlighted above, the degree of automation significantly impacts cost. Fully automatic plants, with their advanced sensors, PLC controls, and integrated systems, demand a higher investment than manual or semi-automatic setups. However, this investment often translates into lower operational costs, higher efficiency, and superior product quality in the long run.

2. Machinery Quality and Brand Reputation

The choice of manufacturer plays a crucial role. Reputable brands like RiceTec Machinery use high-quality raw materials, adhere to stringent manufacturing standards (like ISO and CE certifications), and employ advanced engineering. While these machines might have a higher upfront cost, they offer greater durability, reliability, lower maintenance, and a longer operational life. Inferior quality machines, while cheaper initially, can lead to frequent breakdowns, higher repair costs, and significant production losses.

3. Individual Machine Specifications and Features

Within each category of machinery, there are variations in specifications and features that affect price. For example:

- De-huskers: The type of rubber rollers (e.g., standard, high-performance) and feeder mechanisms.

- Whiteners/Polishers: The number of polishing passes, the type of abrasive rolls, and the presence of silky polishers for enhanced gloss.

- Graders: The precision of grading, the number of screens, and the capacity for fine sorting.

- Dust Collection Systems: The efficiency of dust capture, the filtration technology, and compliance with environmental regulations.

- Power Efficiency: Machines designed for lower power consumption can have a higher initial price but offer substantial long-term savings on electricity bills.

4. Customization and Configuration

Every milling operation has unique requirements based on the type of paddy, desired output quality, and available space. A customized plant design, tailored to specific needs, will impact the overall cost. This can include specialized conveyors, additional storage silos, or integration with other processing lines.

5. Installation and Commissioning

The complexity of the installation process and the expertise required for commissioning the plant will add to the overall cost. Reputable manufacturers often provide on-site installation, testing, and training, which is crucial for optimal performance and operator safety.

6. After-Sales Service and Warranty

Comprehensive after-sales support, including spare parts availability, technical assistance, and warranty coverage, is invaluable. While this might be factored into the initial price, it provides peace of mind and minimizes downtime, protecting your investment. RiceTec Machinery prides itself on offering robust after-sales support and readily available spare parts.

7. Transportation and Logistics

The cost of transporting machinery from the manufacturing facility to your site, especially for larger plants, needs to be considered. This includes freight charges, insurance, and handling.

8. Civil Works and Infrastructure

The price of the rice mill itself doesn’t include the cost of land acquisition, civil construction (building foundations, mill structures, godowns), and utility connections (electricity, water). These are significant investments that must be factored into the total project cost.

9. Market Dynamics and Economic Conditions

Fluctuations in raw material costs (steel, rubber), labor wages, currency exchange rates, and overall economic conditions can influence rice mill prices. Government policies, subsidies, and import duties can also play a role.

The RiceTec Advantage: Value Beyond Price

At RiceTec Machinery, we understand that investing in a rice mill is a significant decision. Our philosophy revolves around delivering not just machinery, but complete milling solutions that offer long-term value and profitability. While we offer competitive pricing across our range of small, medium, and large-scale rice mills, our focus is on:

- Superior Quality: We utilize the finest raw materials and cutting-edge manufacturing processes to build machines that are robust, durable, and perform consistently for years. Our ISO and CE certifications are a testament to our commitment to quality.

- Innovative Technology: Our continuous research and development ensure that our machines incorporate the latest advancements in milling technology, leading to higher efficiency, reduced losses, and superior rice quality. This includes advanced separation, precise grading, and gentle polishing techniques.

- Energy Efficiency: We design our machines to optimize energy consumption, helping you reduce operational costs and contribute to a more sustainable environment.

- Customized Solutions: We work closely with our clients to understand their specific needs and design a milling plant that perfectly fits their requirements, whether it’s a compact mini mill or a large, fully automated facility.

- Comprehensive Support: From initial consultation and plant design to seamless installation, operator training, and reliable after-sales service, we are with you every step of the way. Our extensive network ensures prompt service and spare parts availability.

- Proven Reliability: With over a decade of experience and thousands of satisfied customers across India and neighboring countries, RiceTec Machinery has earned a reputation for reliability and trust.

Making an Informed Decision

When evaluating rice mill prices, it’s essential to look beyond the initial quotation. Consider the total cost of ownership, which includes:

- Initial Investment: The price of the machinery, installation, and civil works.

- Operational Costs: Electricity consumption, labor, maintenance, and spare parts.

- Production Efficiency: Head rice recovery rate, broken rice percentage, and processing speed.

- Product Quality: The market value of the output rice.

- Lifespan and Depreciation: The expected operational life of the machinery.

A seemingly lower upfront cost might result in higher operational expenses, frequent breakdowns, and lower quality output, ultimately impacting your profitability. Investing in a higher quality, more efficient rice mill from a reputable manufacturer like RiceTec Machinery can lead to significant long-term savings and a healthier return on investment.

We encourage prospective buyers to:

- Define your capacity needs: Accurately assess your current and projected paddy processing volume.

- Prioritize quality and reliability: Choose a manufacturer known for durable and efficient machinery.

- Factor in automation: Consider the long-term benefits of reduced labor and increased precision.

- Demand comprehensive support: Ensure the manufacturer offers strong after-sales service and spare parts.

- Request detailed proposals: Obtain itemized breakdowns of machinery, installation, and other associated costs.

At RiceTec Machinery, we are committed to helping you navigate the complexities of rice mill pricing and find the perfect solution for your business. Our team of experts is ready to provide tailored advice and comprehensive quotes, ensuring your investment is well-placed for success.

Frequently Asked Questions about Rice Mill Prices

Q1: What is the minimum investment required to start a small-scale rice mill in India?

A1: A small-scale rice mill, with a capacity of 1-3 tons per hour, typically requires an investment ranging from ₹10 lakhs to ₹25 lakhs in India. This includes the cost of basic machinery, but excludes land and civil works.

Q2: How does automation affect the rice mill price?

A2: Automation significantly increases the initial price of a rice mill. Fully automatic plants, due to their advanced technology, sensors, and PLC control systems, are considerably more expensive than semi-automatic or manual mills. However, automation leads to higher efficiency, reduced labor costs, consistent quality, and lower long-term operational expenses.

Q3: What are the main components that contribute to the overall rice mill price?

A3: The main components contributing to the overall rice mill price include the cost of individual machines (pre-cleaner, de-husker, paddy separator, whitener, polisher, grader, sifter), material handling equipment (elevators, conveyors), electrical panels, automation systems, installation and commissioning charges, and freight. Land and civil infrastructure are separate significant costs.

Q4: Is it more cost-effective to buy individual machines or a complete rice mill plant?

A4: For a new milling operation, purchasing a complete rice mill plant from a single manufacturer is generally more cost-effective and efficient. It ensures seamless integration of all components, optimized performance, and a single point of contact for service and support. Individual machines might be suitable for upgrading existing facilities or for very niche requirements.

Q5: What kind of after-sales service should I expect for my rice mill investment?

A5: A reputable manufacturer should offer comprehensive after-sales service, including on-site installation support, operator training, readily available spare parts, and prompt technical assistance for troubleshooting and maintenance. This ensures minimal downtime and a longer lifespan for your machinery.

Q6: How important is power consumption when considering the rice mill price?

A6: Power consumption is a critical factor influencing the long-term operational cost of a rice mill. While energy-efficient machines might have a slightly higher initial price, they lead to substantial savings on electricity bills over time. It’s essential to inquire about the power requirements and energy efficiency ratings of the machinery before making a purchase.

Q7: Can I get customized rice mill solutions based on my specific needs?

A7: Yes, most reputable rice mill manufacturers offer customized solutions. They will assess your paddy type, desired output quality, capacity requirements, and available space to design a plant that perfectly fits your specific operational needs. This personalized approach can optimize efficiency and profitability.

Q8: What is the typical lifespan of a well-maintained rice mill machine?

A8: With proper maintenance, regular servicing, and the use of genuine spare parts, a high-quality rice mill machine from a reputable manufacturer can have a lifespan of 15-20 years or even more. The longevity is heavily dependent on the quality of the components and adherence to maintenance schedules.